concrete

Retail Store Build-Out

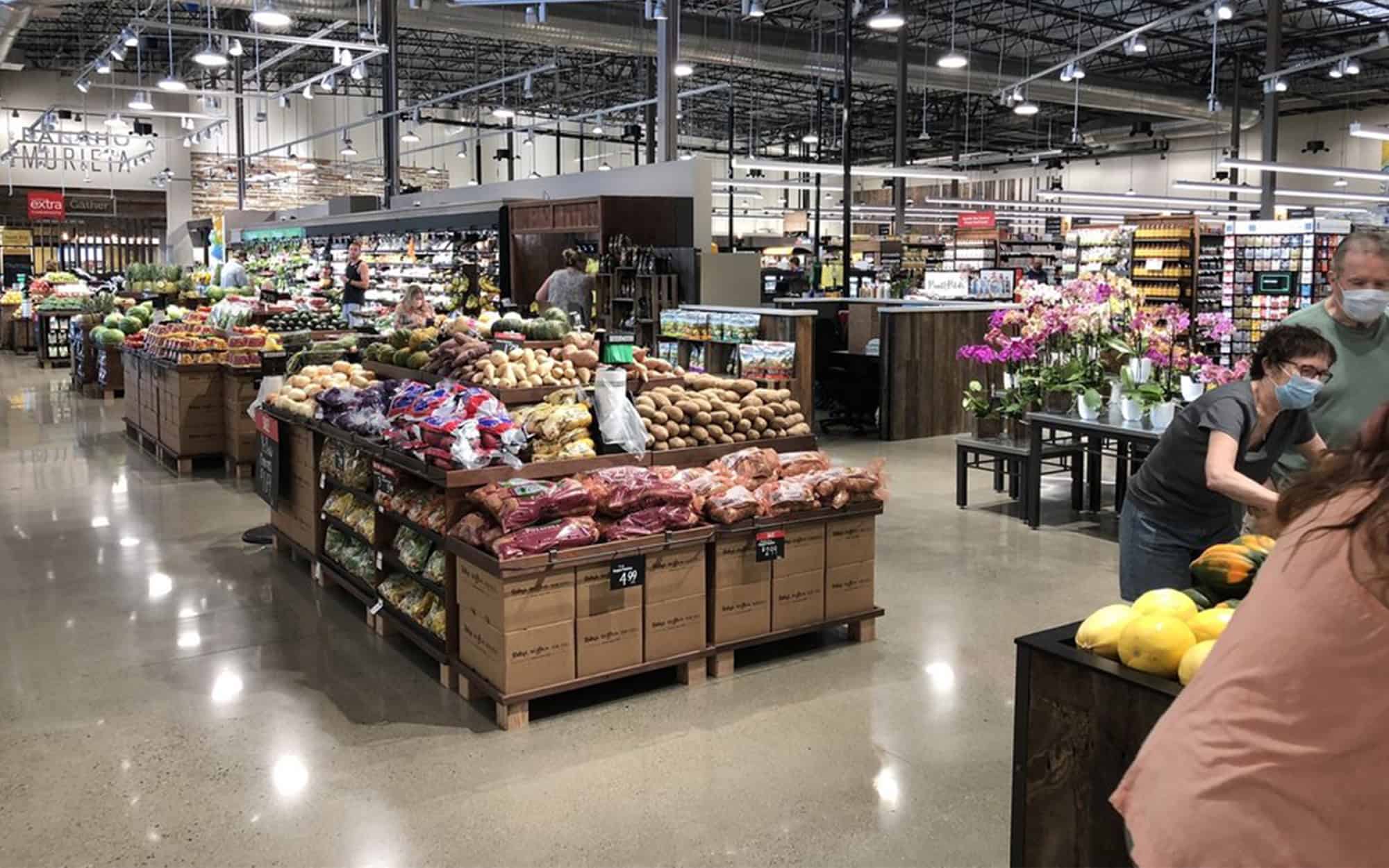

Concrete work for retail store construction and tenant improvements

Request Service

Get Free Estimate(817) 796-9459Fast response (24-48 hours)

Direct-to-owner bidding

Serving Johnson County & DFW

Retail store build-out concrete services provide tenant improvement construction for new retail spaces throughout Cleburne and Johnson County, TX. As retail developers and national chains establish presence in growing markets along the Chisholm Trail corridor, professional concrete work forms the foundation of successful store openings, from structural slabs and foundations to polished concrete floors, decorative paving, and specialty installations. Build-out projects operate under aggressive schedules driven by lease commitments and seasonal opening targets, requiring experienced contractors coordinating concrete work with parallel trades while maintaining quality standards essential for long-term store performance.

Retail build-outs typically involve interior slab-on-grade construction for new pad sites or conversion of existing warehouse/commercial space to retail use. New construction requires complete foundation and floor slab systems designed for retail loading (typically lighter than distribution uses but requiring aesthetic finishes), coordinated utility rough-ins, and surface finishes appropriate for retail flooring applications. Polished concrete has become increasingly popular for retail floors offering contemporary aesthetics, low maintenance, and cost savings compared to traditional flooring systems while supporting LEED certification goals for sustainable retail development.

Schedule is paramount in retail construction where delayed openings directly impact revenue and lease obligations. A typical 5,000-10,000 square foot retail tenant improvement proceeds from concrete work to certificate of occupancy in 12-16 weeks, with foundation and floor slab completing in first 2-3 weeks establishing critical path for all following trades. Night and weekend work is common accommodating aggressive schedules, while rapid-set materials and accelerated curing techniques compress timelines without compromising quality.

Our retail build-out concrete services include complete tenant improvement planning and coordination, foundation design and construction for new pad buildings, interior slab-on-grade systems with integrated utilities, polished concrete floor installation from grinding through final sealing, decorative concrete for entries and featured areas, coordination with parallel trades minimizing conflicts and delays, and fast-track scheduling techniques meeting aggressive opening deadlines. Whether you're developing a 3,000 SF inline shop or a 50,000 SF anchor store, professional concrete expertise ensures retail spaces open on schedule with quality construction supporting decades of successful operations in Johnson County's competitive retail market.

Common Applications

Inline Tenant Spaces

Inline retail spaces ranging from 1,200-5,000 square feet within shopping centers require economical, fast-track concrete construction. Typical work includes interior slab-on-grade (4-5 inches thick, 3,000-3,500 PSI) with integrated plumbing and electrical rough-ins, coordination with storefront installation, and floor finishes supporting tenant flooring selections or polished concrete. Slabs must accommodate future flexibility as retail tenants change frequently, every 5-10 years on average. Utility sleeves are positioned generously allowing tenant modifications without concrete sawcutting. Schedule is critical as lease commencement dates drive revenue, making on-time completion essential for landlord-tenant relationships and avoiding costly lease delays.

Junior & Major Anchor Stores

Anchor tenants (15,000-80,000 SF) drive shopping center success and receive priority scheduling and construction attention. Concrete work includes substantial foundation systems for new buildings, large-format slabs requiring laser screed for flatness, extensive utility coordination for complex retail HVAC and electrical systems, and often polished concrete floors in sales areas combined with standard slabs in storage and receiving. These projects may include loading docks, exterior paving connecting to parking and pedestrian networks, and decorative concrete at main entries creating upscale first impressions. Anchors have sophisticated construction management teams enforcing strict quality and schedule requirements: professional execution is essential for future work with national retailers expanding in Texas markets.

Restaurant Build-Outs

Restaurant tenant improvements present unique concrete challenges including grease traps and floor drains requiring extensive below-slab plumbing, sloped floor areas directing water to drains meeting health codes, floor finishes withstanding frequent washing and food service operations, and exterior patio slabs with decorative finishes creating attractive dining environments. Quick-service restaurants operate on compressed 8-10 week build-out schedules from lease signing to opening, requiring exceptional coordination and fast-track techniques. Full-service restaurants involve more extensive work but typically allow 12-16 week schedules. All restaurant concrete must meet health department requirements for cleanability, drainage, and sanitation. We maintain familiarity with Johnson County health codes ensuring approvals without delays.

Conversion & Adaptive Reuse

Converting existing warehouse, office, or industrial space to retail use often requires substantial concrete modification: removing and replacing deteriorated slabs, adding floor drains and utility rough-ins, leveling settled floors, and installing polished concrete or other finishes appropriate for retail environments. These projects present challenges from unknown existing conditions, asbestos or lead paint requiring abatement, contaminated soils from previous industrial use, and coordinating work in occupied buildings. Careful investigation and planning prevents surprises delaying schedules or exceeding budgets. Adaptive reuse projects contribute to sustainable development reusing existing structures rather than new construction, appealing to environmentally-conscious retailers seeking LEED certification and community goodwill in Johnson County markets.

Technical Specifications

Retail Slab Specifications

Retail store slabs typically use 4-5 inch thickness providing adequate strength for foot traffic, display fixtures, and light equipment while minimizing cost and schedule. Concrete strength is 3,000-3,500 PSI for standard retail, increasing to 4,000 PSI for heavy fixtures or polished concrete applications. Fiber reinforcement (3-5 lbs per cubic yard) provides crack control without labor-intensive rebar installation: important for fast-track schedules. Slabs receive vapor barriers (10-15 mil polyethylene) preventing moisture migration that could damage flooring systems. For polished concrete applications, low water-cement ratio (under 0.45) improves surface hardness and reduces shrinkage cracking.

Utility Coordination

Retail slabs accommodate extensive utility rough-ins requiring careful coordination. Plumbing includes drain lines for restrooms, janitor closets, and food service (if applicable), with floor drains positioned per health codes and architectural layouts. Electrical conduits for power, lighting, and data are positioned avoiding conflicts with plumbing while meeting code requirements for service locations. HVAC may include refrigerant lines or condensate drains penetrating slabs. All utilities are installed before base material and vapor barrier, with penetrations properly sealed preventing moisture infiltration. Utility locations are documented on as-built drawings for future tenant modifications.

Polished Concrete for Retail

Polished concrete has become the preferred flooring for many retail applications offering contemporary aesthetics, low maintenance, and cost-effectiveness. The process uses diamond grinding tools progressively refining slab surfaces through multiple grits creating specified appearance from cream finish (minimal aggregate exposure) to full exposure (large decorative aggregate visible). Chemical densifiers penetrate concrete increasing surface hardness to 7-9 on Mohs scale: comparable to granite. Final gloss levels range from matte (honed) suitable for rustic retail concepts to high-gloss creating upscale contemporary appearances. Polished concrete coordinates with retail design creating floor patterns, color variations, or decorative scoring reinforcing store branding while maintaining durable, easily-maintained surfaces.

Fast-Track Materials & Methods

Retail construction schedules often demand accelerated concrete timelines. Rapid-set concrete achieves 3,000+ PSI in 3-4 hours versus 7 days for standard concrete, allowing earlier trades access and compressing critical path. High-early strength concrete (Type III cement or accelerators) achieves adequate strength in 3-5 days. For polished concrete, early-age grinding can begin at 7 days with certain mix designs versus typical 14-28 days. Heated enclosures maintain curing temperatures in winter accelerating strength gain. These techniques carry cost premiums and require experienced crews managing short working times, but may be justified when schedule delays cost thousands per day in lost revenue or lease penalties.

ADA Compliance

Retail tenant improvements must meet ADA accessibility requirements for sales floors, restrooms, and customer areas. Maximum floor slopes are 1:48 (2%) for accessible routes, with ramps requiring 1:12 maximum slope, handrails, and level landings. Transitions between materials (carpet to tile, polished concrete to mat wells) cannot exceed 1/4 inch vertical change or require beveled edges. Accessible routes maintain minimum 36-inch clear width (48 inches preferred) from entries through sales areas to all customer services. Thresholds at doors cannot exceed 1/2 inch height. All work undergoes plan review and inspection by Cleburne Building Inspections verifying ADA compliance before certificates of occupancy are issued.

Project Timeline

Pre-Construction Coordination

Review architectural and MEP plans identifying concrete scope, utility rough-in requirements, and schedule constraints. Coordinate with general contractor, architect, and owner establishing schedule milestones aligned with lease commencement and opening dates. Submit shop drawings showing slab details, joints, penetrations, and embeds for approval. Order materials ensuring availability for tight construction windows. Obtain building permits and schedule inspections with Cleburne Building Inspections.

1-2 weeks prior to site mobilization

Site Preparation

For new pad buildings, clear site and establish grades per civil plans. For tenant improvements in existing buildings, demolish existing finishes exposing substrate, remove unsuitable materials, and prepare for new slab installation. Install temporary utilities, establish material staging areas, and protect adjacent tenant spaces from construction impacts. Coordinate with shopping center management establishing construction hours, access routes, and safety protocols.

2-4 days

Foundation Work (new buildings)

Excavate for spread footings or drilled piers per geotechnical recommendations, install reinforcement and anchor bolts, place foundation concrete with required inspections. For Johnson County expansive soils, foundations typically use drilled pier and grade beam systems. Foundation construction coordinates with building shell erection (tilt-wall or steel frame), with concrete work proceeding while parallel trades advance building envelope.

1-2 weeks for typical retail pad

Underslab Utilities

Install plumbing rough-ins including drain lines, floor drains, grease traps (restaurants), and water service penetrations. Electrical conduits for power, data, and lighting are positioned per plans. HVAC ductwork beneath slab (if applicable) is installed and protected. All utility installations are pressure-tested and inspected before slab preparation proceeds. Proper coordination prevents conflicts and costly post-slab modifications.

3-7 days depending on complexity

Slab Preparation & Placement

Install vapor barrier and compacted base material per specifications. Position reinforcement (fiber or welded wire fabric), verify utility penetrations, and coordinate final inspection before concrete placement. Place and finish concrete to specified thickness and surface texture, typically broom finish for tenant flooring or trowel finish for polished concrete applications. Immediate curing prevents plastic shrinkage in Cleburne climate.

1-3 days for typical retail space

Joint Cutting & Curing

Saw-cut control joints within 12-24 hours creating appropriate panel sizes controlling shrinkage cracking. Slab cures minimum 7 days before heavy construction loads, though light traffic (workers, small equipment) may be permitted after 3-4 days in summer temperatures. For fast-track projects, accelerated curing methods or rapid-set materials compress schedules. Coordination with following trades ensures slab is ready for their work without delays.

7-14 days curing, 1-2 days joint cutting

Polished Concrete (if applicable)

After minimum 14-day slab cure, diamond grinding begins progressively refining surface through multiple grits (30/40, 80, 120, 400). Chemical densifiers are applied penetrating and hardening concrete. Final polishing pads (800-3000 grit) create specified gloss level from matte to high-gloss. Work is scheduled after drywall and painting completion preventing dust contamination of finished surfaces, but before final fixtures, millwork, and merchandise installation avoiding damage from equipment.

5-7 days depending on floor area and finish spec

Cleburne & Johnson County Considerations

Chisholm Trail Retail Development: The Chisholm Trail Parkway corridor through Cleburne and Johnson County has driven substantial retail development as major retailers establish presence serving growing populations. New shopping centers, pad site development, and tenant turnover in existing centers creates consistent demand for retail build-out concrete services. Projects benefit from established development patterns. Shopping centers cluster along the corridor enabling efficient mobilization between nearby projects, local suppliers understand retail construction demands providing reliable material delivery, and inspection departments are familiar with national retailer requirements streamlining approvals. Competition for experienced crews during peak construction seasons (spring/fall) requires advance scheduling and maintaining relationships with multiple trade partners ensuring capacity for time-sensitive retail projects.

Shopping Center Construction Protocols: Retail build-outs in operating shopping centers must comply with strict owner and management rules protecting existing tenants and maintaining positive customer experience during construction. Common requirements include limiting noisy work to off-hours (typically before 10 AM weekdays, weekends, or nights), using dust barriers preventing migration to adjacent spaces, scheduling concrete deliveries avoiding peak shopping hours (typically 11 AM - 3 PM and 5 PM - 7 PM), maintaining pedestrian access and safety throughout construction, and requiring insurance and bonding protecting property owners. Some premier centers prohibit concrete trucks on-site during shopping hours necessitating night pours or weekend work. We maintain extensive experience working within these constraints, coordinating schedules, implementing comprehensive dust and noise control, and maintaining professional site conditions that preserve positive relationships with property management enabling future projects throughout Johnson County's retail development market.

Frequently Asked Questions

Related Services

Tenant Improvement Concrete

Concrete services for commercial tenant improvements and build-outs

Learn More →Retail Space Renovation

Concrete renovation for retail store remodels and updates

Learn More →Commercial Fit-Out Services

Complete concrete fit-out services for commercial and retail spaces

Learn More →Service Areas

We provide retail store build-out throughout Cleburne and Johnson County:

Ready to Start Your Retail Store Build-Out Project?

Get a detailed estimate for your commercial concrete project. Our team responds within 24 hours with crew size, schedule, and pricing.